Cruise ships residence lots of of passengers and crew, which results in monumental wastewater expertise of as a lot as 1000 cubic metres per day. Due to this fact, Wastewater administration has develop to be a important side of frequently operations.

A cruise ship should be self-reliant on this side, as a result of it stays away from land for a considerable time interval.

Wastewater onboard cruise ships are categorised into two kinds, significantly, greywater & blackwater.

Greywater comes from loos, showers and washbasins. The water from galleys, meat rooms, fish rooms and laundries may also be greywater. Nonetheless, such water is called galley & laundry grey water for ease of differentiation.

Blackwater is the dirty water from bogs and urinals, along with flushed water. As a result of it consists of human waste, which is infectious & an environmental hazard, it needs specific coping with & treatment processes for its storage onboard or its discharge overboard outside ecological limits.

Attributable to this reality, our deal with this text shall be on blackwater administration, treatment and disposal.

Related finding out:

Blackwater Assortment & Segregation/Pre-treatment

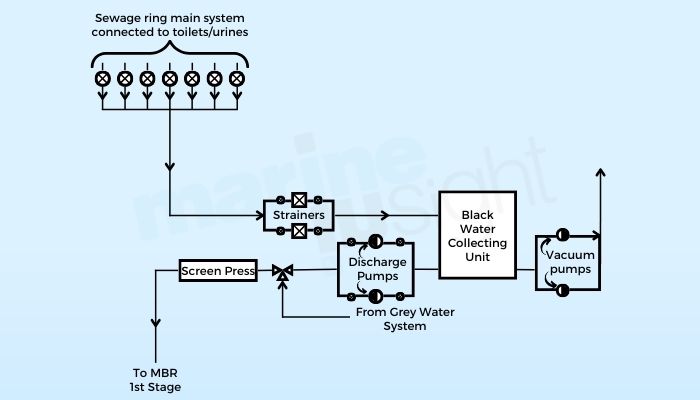

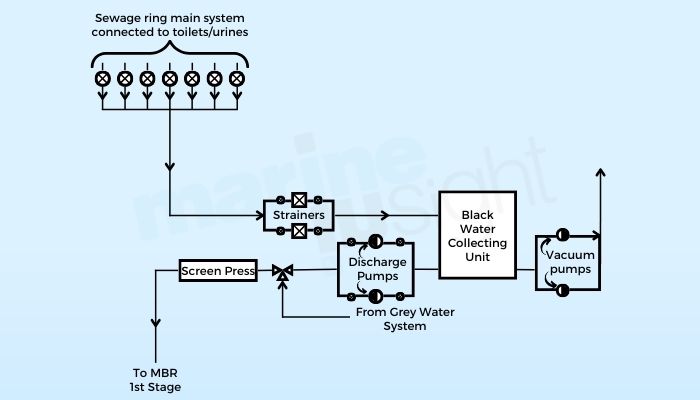

Blackwater is collected in blackwater accumulating fashions by the use of a ring-main system. The ring-main system is break up by assorted decks or zones onboard and associated to completely totally different blackwater accumulating fashions.

There is likely to be numerous numbers of accumulating fashions (4-10 fashions) relying upon the dimensions of the ship. They’re usually put in in technical areas all via the ship, the place technical staff can monitor and protect them.

The blackwater is collected inside the accumulating tanks by gravity or vacuum. Inside the case of a vacuum system, the vacuum is generated inside the accumulating tank & its suction line using linked vacuum pumps which operate per the vacuum diploma by way of sensors.

The blackwater goes to the accumulating fashions by way of coarse strainers, which need to be cleaned day-to-day or as per demand. These strainers take away any large-sized solids that can go to the accumulating tanks, clog pipework or the discharge pumps.

The blackwater accumulating fashions have linked discharge pumps which will be normally set to work on a timer nevertheless will be set to work on the extent. The pumps are operated by float switches and performance sometimes to lower the extent of the blackwater accumulating fashions. These pumps are sewage discharge pumps and change the blackwater from the accumulating fashions to show presses.

The show presses extra separate the solids, akin to bathroom paper, plastics, grit, fibres, rags and lots of others., from the blackwater, thus guaranteeing that solely the liquid passes by way of to the following stage, which is the treatment stage.

That’s completed by first separating the larger-sized solids by a mesh often known as a show and, after that, eradicating the good suspended steady impurities by an enormous screw shaft operated by a motor, which grinds and separates out the finer solids.

The screened or filtered blackwater passes by way of to the following stage, the treatment stage, whereas the separated solids from the show press are collected in a separate tank, usually typically often known as a Bio-sludge tank.

Accommodated greywater will be fed to the MBRs along with blackwater. This course of is routinely managed as per demand, with the help of a 3-way valve on the inlet to the show presses. At events of low blackwater expertise, which is often at night time time when most people are asleep, the 3-way valve gives greywater to the MBR system to care for the levels of the phases.

Inside the above case, the lodging greywater is saved in separate double-bottom tanks. MBR greywater pumps are supplied, which operate routinely as per the greywater demand from the MBR and the extent of greywater inside the DB tanks.

Remedy Course of

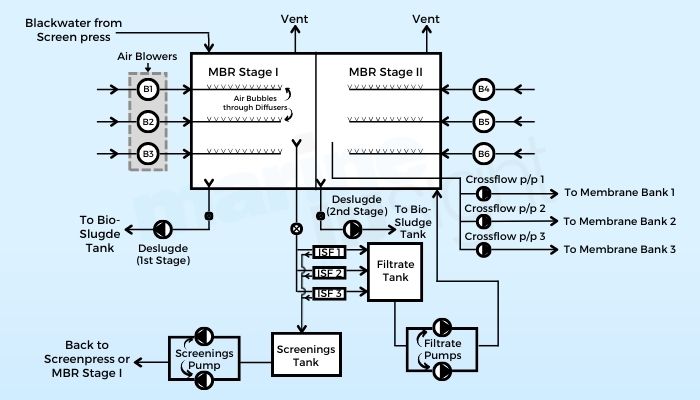

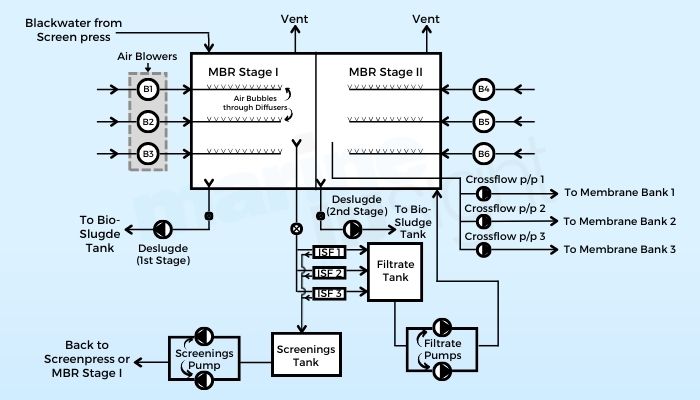

The screened/filtered blackwater goes to the sewage treatment plant typically often known as MBR. MBR stands for Membrane Bio-Reactor. As a result of the title suggests, it treats sewage or blackwater by way of natural processes and membrane filtration.

The MBR has two phases. The blackwater from the show presses includes the 1st stage, the place cardio micro organism take care of it. A seamless air present generates cardio micro organism by way of blowers and diffusers, which create air bubbles for evenly distributing the air all via the biomass. Additional air, water vapour & gases are vented from every phases by linked vent traces to the ambiance.

The cardio micro organism act on the sewage, thus breaking it down & separating the sludge from the sewage water. The dealt with water now passes by way of to the 2nd stage of the MBR, by way of the ISFs, which stands for Inter-Stage Filters.

The ISFs help to remove any finer particles or impurities that can have been generated inside the first stage or carried over from the pre-treatment stage. The filtrate from the ISF is collected in an linked filtrate tank, from the place it is pumped to the 2nd stage of the MBR by filtrate pumps, whereas the separated screenings (solids) collected inside the screenings tank and are each pumped once more to the show press or the 1st stage by the screening pumps. Every the filtrate & screenings pump has one operational pump & one standby pump.

The state of affairs of the ISFs need to be incessantly checked, and the filters cleaned if required. The filtrate to screenings ratio is a parameter that signifies the nicely being of the ISFs. Usually, the ratio must be between 1 and 5. Readings correctly outside this range will necessitate checks and/or modifications.

Like inside the 1st stage, extra cardio movement moreover takes place inside the 2nd stage. That’s to guarantee that sludge separation takes place as loads as doable so that solely liquid passes by way of to the membrane-filtration stage, thus reducing the potential of membrane clogging and/or breakage, which can find yourself in downtime and elevated repairs.

The separated sludge from every the 1st stage & 2nd stage need to be eradicated day-to-day to cease the unintentional carryover of the sludge along with the liquid to the membrane. There are separate sludge pumps and tanks which can be supplied for that goal. Chemical dosing may also be completed in every phases for sewage sludge conditioning.

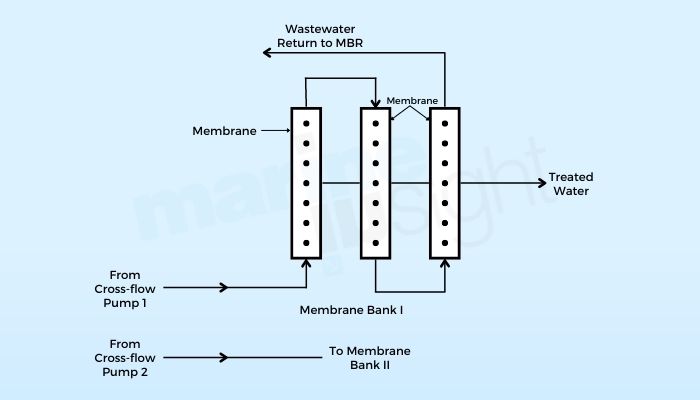

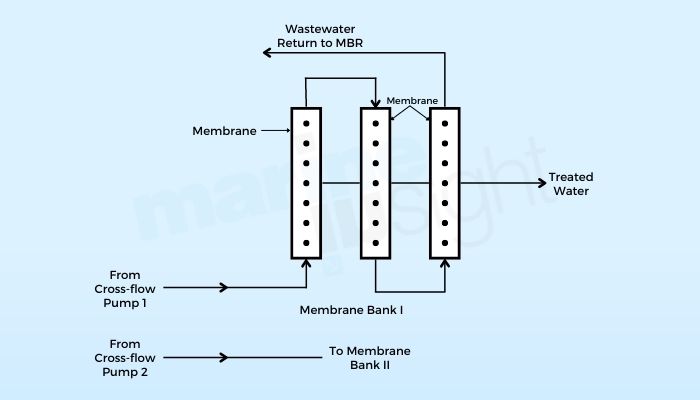

The liquid (wastewater) beneath treatment is pumped from the bioreactor’s 2nd stage to the membranes by the centrifugal crossflow pumps. The membranes are usually organized in numerous (usually 3 to 4) parallel banks. Each monetary establishment has numerous membranes in sequence & its crossflow pump. The particular person banks is likely to be isolated for cleaning or repairs with out disturbing the strategy.

Each membrane is tubular, with 8 mm nominal bore tubes mounted onto 200 mm nominal diameter fibre-reinforced casings. The membranes are rated inside the ultra-filtration range, with a nominal pore dimension of 40 nanometres.

There are a variety of billions of such microscopic pores on the ground of the membrane fibre, which whereas forming a barrier to microbial impurities akin to micro organism, viruses and protozoa, allow pure water molecules to go by way of, thus affecting treatment. The untreated wastewater recirculates once more to the bioreactor 2nd stage.

The membrane banks, which foul as a consequence of accumulation of impurities, need to be backflushed or flushed with clear freshwater as quickly as on daily basis and chemically cleaned as quickly as per week for continued operational reliability and to avoid breakdown and damage to membranes. Membrane various may very well be a costly and time-taking affair.

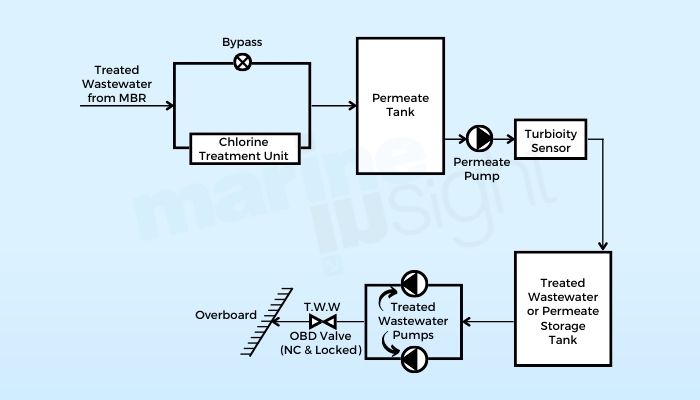

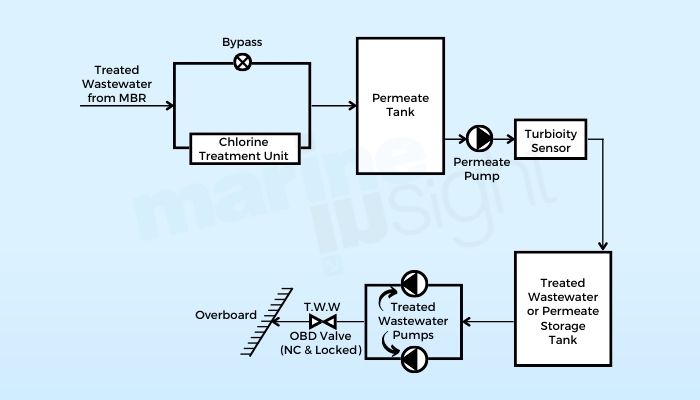

The membrane-filtered liquid, typically often known as permeate or dealt with wastewater, is also dealt with with chlorine for extra disinfection sooner than being pumped to permeate or dealt with wastewater storage tanks by way of a Turbidity sensor, which stops the permeate pump in case of extreme turbidity.

The saved permeate is pumped overboard, if & when outside of environmental limits, by dealt with wastewater pumps. Chlorine treatment (disinfection), inside the case of MBRs, is not going to be usually essential if the bio-reactor & membranes are performing correctly.

Weekly assessments need to be carried out for Natural/Chemical Oxygen Demand, odor, shade and E-Coli by taking samples from every phases of the bio-reactors permeate to determine the effectivity of the MBR plant.

Whereas lodging greywater is likely to be geared up to the MBR, it is not advisable to utilize galley & laundry greywater, as a result of the presence of detergents and/or oils can most likely be detrimental to the cardio micro organism, thereby affecting biomass expertise and efficiency. For that purpose, galley and laundry greywater even have their very personal separate storage tanks.

Blackwater administration is a fancy course of that calls for an entire understanding of the system, strict consideration to parameters, adherence to appropriate & nicely timed repairs procedures and proper troubleshooting for continued effectivity and operational continuity.

The system’s complexity will be a component inside the dimension of the ship. Bigger ships will put a considerable load by the use of operations & routines. Although designed to operate routinely and with out handbook assist, strategies are always susceptible to failure. It is advisable to look at producer suggestions, manuals, repairs schedules & widespread testing to determine the plant’s nicely being.

You may additionally desire to read-

Disclaimer :

The info contained on this web page is for widespread data features solely. Whereas we endeavour to take care of the information up to date and correct, we make no representations or warranties of any kind, particular or implied, regarding the completeness, accuracy, reliability, suitability or availability with respect to the web page or the information, merchandise, firms, or related graphics contained on the internet web site for any goal. Any reliance you place on such data is subsequently strictly at your particular person hazard.

In no event will we be answerable for any loss or damage along with with out limitation, indirect or consequential loss or damage, or any loss or damage in anyway arising from lack of understanding or earnings arising out of, or in reference to, utilizing this web page.

Disclaimer :

The info contained on this web page is for widespread data features solely. Whereas we endeavour to take care of the information up to date and correct, we make no representations or warranties of any kind, particular or implied, regarding the completeness, accuracy, reliability, suitability or availability with respect to the web page or the information, merchandise, firms, or related graphics contained on the internet web site for any goal. Any reliance you place on such data is subsequently strictly at your particular person hazard.

About Creator

Ramanan Sethuraman is a marine engineer who has over a decade of experience in transport. Having started his occupation with cargo ships, he later shifted to passenger liners and have sailed with reputed cruise traces. In his free time he likes finding out, writing, sports activities actions and travelling.

Be taught Additional Articles By This Creator >

Daily Maritime Info, Straight To Your Inbox

Sign Up To Get Daily Newsletters

Be a part of over 60k+ people who study our day-to-day newsletters

By subscribing, you adjust to our Privateness Protection and can get hold of occasional deal communications; chances are you’ll unsubscribe anytime.